- Services

Quality Dimensions

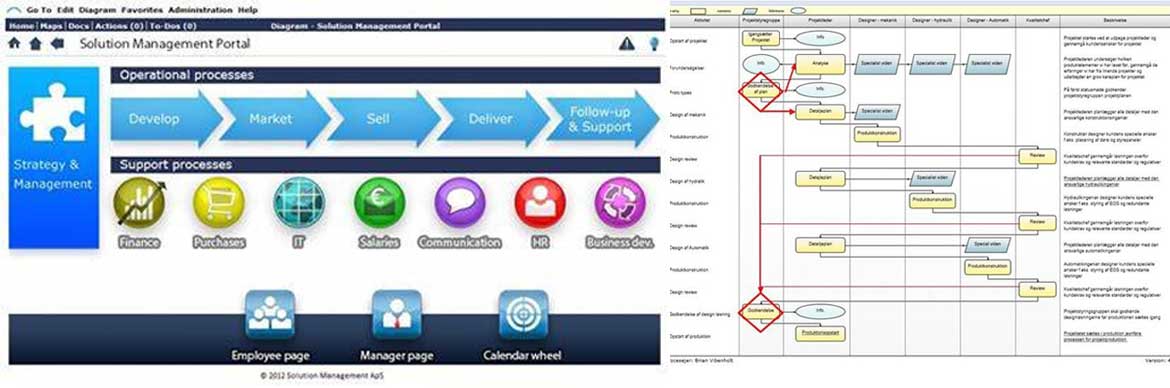

Integrated ISO Standard systems

Integrated ALL ISO standards management handbook into generic software.

Since the 2015 edition of most of the ISO standard it is possible to integrate the most of the ISO standard in to one electronic version. Vibenholt Consultancy provide you with an all-in ISO standard electronic handbook, certifiable according to ISO 9001, ISO 14001, ISO 45001 etc.

Sourcing quality management

Vibenholt Quality Strategies secure the quality of your sourcing from Asia or Eastern Europe, both securing product compliance to your specification and securing the supplier fulfill CSR standards and to high quality requirements.

During decades we have seen that western companies have placed their order or outsource the production to Asia, especially China and hereafter have problems with the delivered goods. Why?

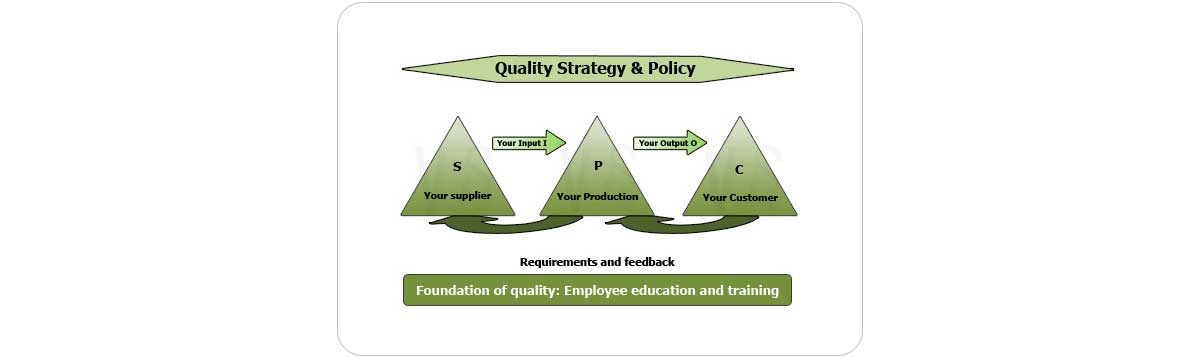

One of the mayor reasons that sourcing from foreign culture fails is lack of specific requirements and supervision. Getting the goods produced in a location far from the daily reaches of supervision require a higher effort in the requirement to both product specification and local quality system.

You get what you pay! But if you require more you get more! You just have to be specific, in requirement for the product, production technology, the supplies’ quality system and the way they report to you.

Over a period of 12 years in Asia I have see that engagement in sourcing quality pay off, those who involve them self in the production of their goods get the same high quality products as they can get in Western Europe, - it still cost less.

To improve your’ sourcing from Asia, a thorough assessment has to be carried out, what value do your supplier bring you and your customer? Does your supplier master the quality risks?

Each company has its own challenges, describe your challenge in sourcing from Asia in the textbox and I will find a way to help you.

Supplier assessment management tools are a part of the package Vibenholt Quality Strategies offer. Assessments can be done in two ways, as single assessment and audit as well as running delivery monitoring tools.

Quality Strategies:

Vibenholt Quality Strategies can guide you to take the right strategy decisions regarding quality, to secure a continuous improvement of the quality system, design validation, sourcing policy, production optimization, thus the quality product the customer needs.

Primary consulting areas:

Quality business process analyze: Is it the strategy to aim for the big A1 quality diploma or is it sufficient to have the right competitive advantage with a simple quality hand book and a standard ISO 9001 certificate?

The span between the A1 and a simple system is significant, and the effort of quality system engagement has to pay off, by increase turnover or lower cost (including minimizing waist of resources)

Identification of the customer quality requirement: Do you deliver the product the customer as for? Often the demand for quality is unspoken. But a mistake in the design has a significant impact when the customer evaluates you as a reliable supplier.

A business analyze of the quality activities and quality development: a case study is advisable before the big quality project is launched.

The company strategy can be sub divided in a number of specific strategies for the company focus, however, the quality strategy go vertical down through the organization.

What is important in the strategy work for your?

Try to answer these questions:

> Go back three years, take your strategies from then, can you recognize them? And did you achieve your goal for this year by using these strategies? If not when why?

> Go one year back and ask the same questions.

> In your quality management review, did you analyze the gap between the corporate strategies to the action plan from last quality management review? Is the action plan from the quality management review in line with the corporate strategy?

> Is your strategies based on the company’s and suppliers capability?

> For how long time over the year are you in line with your strategies?

If any of these questions raise a concern your strategies are not sustainable, describe your challenge in keeping your strategies on track in the textbox and I will find a way to help you.

Strategy gap analyzing tools are a part of the package Vibenholt Quality Strategies offer.

The quality management system:

Vibenholt Quality Strategies can assist you to establish and maintain your quality aligned to your need and secure that the system is certifiable.

The quality handbook: a company without a quality handbook cannot get a certification, and in very few industries it is possible to stay in business without a quality system certified. The quality handbook has to describe all the processes relevant for the firm to make the business focusing on the core processes, these procedures must be complied, the described procedures is the foundation for produce the right product, and if failing to identify the root cause. For smaller firms the cost of this can be minimized by using consultant.

Internal audit of the quality system: Are we doing it as we described? Is it the procedures according to the standard and do the employee working accordingly? The intern audit is the firm own control of the system, however, to save cost for education of auditors this task can outsourced to a consultant.

Prepare the company’s quality management system: When the customer requirement is that you must have a certification in accordance to a ISO standard, the success rate for achieving the certificate is quite higher using an experienced quality consultant, who know the relevant standard all pitfalls that will result in remarks from the certifying bodies and therefore, can be avoided forehanded.

Try to consider the following questions:

Does your quality management system give value to you?

Do you see the quality management system as spending money with no return if value?

Do your employees see the quality auditor as policeman or friendly help to solve their problems?

Do your employees use and relate to the quality handbook? Can each employee find their role in the processes described in Quality Management System? Do they understand the procedures or do they only work according to the working instruction?

Can your quality management system go through the certification without any remarks?

If any of these questions raise a concern your quality management system is not fit for your organization, and should be improved, describe your challenge in making value in the use of the quality management system and I will find a way to help you.Quality management system tools are a part of the package Vibenholt Quality Strategies offer.

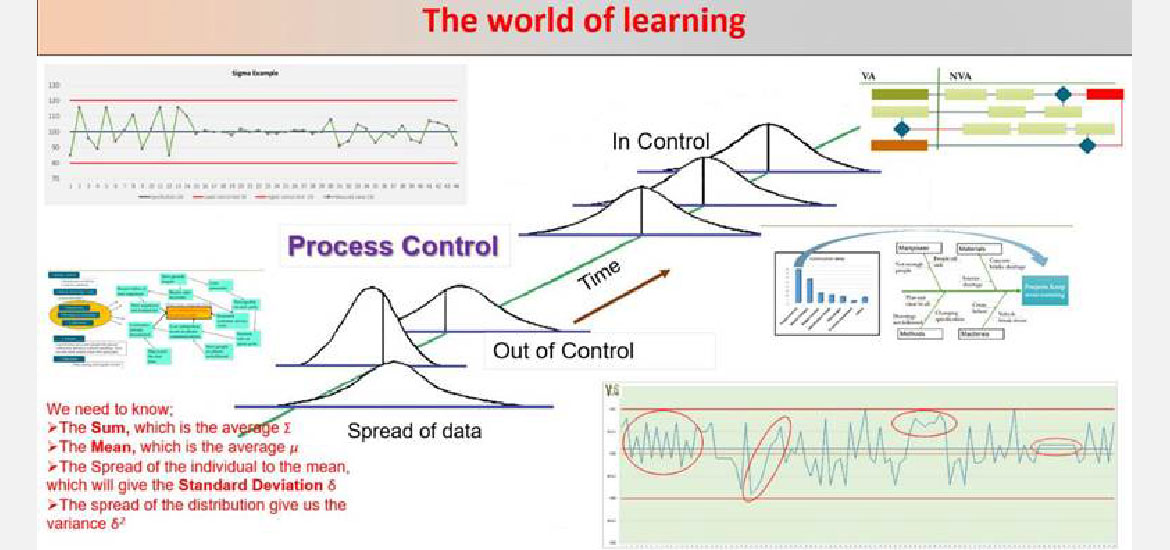

Process optimization & continuous improvement:

Vibenholt Quality Strategies offer leads and guidance projects for improvements of processes, risk assessments and validation of products and sustainable improvements of the effectiveness in the production.

It is the basic to prevent defects to occur and eliminate failure

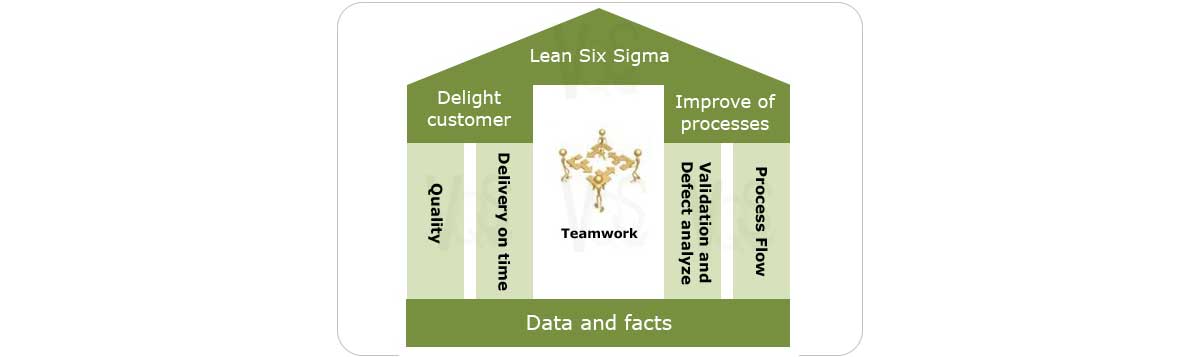

Lean Six sigma projects: Establish the day to day monitoring of the production process in order for continuous improvements.

The critical parameters, that secure the customer get the product they need is important to identify and control in a way where control recourses are minimized. Cost of quality coming from finished good are unacceptable, the production has to be in control from the start to eliminate waste.

Risk assessments: Minimize errors and defects build in the design of the product or preventing errors in the production process.

Validation of products and production: Secure that failures in product development and engineering does not are eliminated before the product is realized for production, thus save cost on late point of time. It has often been seen that solving one problem lead to a even more critical error, when problems are uncritical fixed.

Continuous improvement in the daily routine: All most all production process can be optimized, even the process in fully control will overtime drift out of control due to a long list of circumstances where equipment get worn out and raw material change in variations. Sustainable solution for monitoring and routine maintenances equipment saves cost over time.

Business process improvement is a must for the firm to get competitive advantage and survive.

Improvement comes when we know more about the processes and therefore, can be optimized.

Business excellence analyze: By systematic gather information from customer, production process, employees and design and development (new technology) it is possible to make gab analysis from the strategy to the achieved and from applied resources to the output.

DO you want to improve your business? Can your production be improved?

Do you fully control your quality? Is there a need optimizing production process and reduce waist, but you need the tools to do it. Describe your challenge in getting the best out your production and your employees in the textbox and I will find a way to help you.

Process optimization and continuous improvement tools are a part of the package Vibenholt Quality Strategies offer.

Quality training and education

Vibenholt Quality Strategies provide better insight and understanding of the quality concept and philosophy for the employees in the company.

Tailor made training and education in quality issues based on the specific needs in the company in respect to industry, product portfolio, business processes and production. The tailor education can be aim differently in the organization, the scope of quality is different in the group of managers and the production team, thus the trainings program needs to be specific.

Specific programs or mini projects:

5S programs, avoid wasting your money! Five steps to eliminate loss of resource!

With a systematic work to minimize waste you increase the long time bottom line result.

Kaizen programs, improve the effectiveness of the production by systematic production improvements.

Management seminar in quality culture. If quality is going to be a part of the daily routine, the corporate culture needs to reflect the quality mindset.

Lecture: What is required of a company where quality is a culture?

Lecture: What the customers really want?

Lecture: Do you control your supplier?

Do your employees use and relate to the quality handbook?

Can each employee find their role in the processes described in Quality Management System?

Do they understand the procedures or do they only work according to the working instruction?

Do your employees understand the tool to improve?

Does your employee make errors?

There are a number of reasons to educate the employees, describe your challenge in getting the best out your employees in the textbox and I will find a way to help you

With 14 premade education lessons; tailor made training and education for all in your organization is Vibenholt Quality Strategies offer.